热门文章

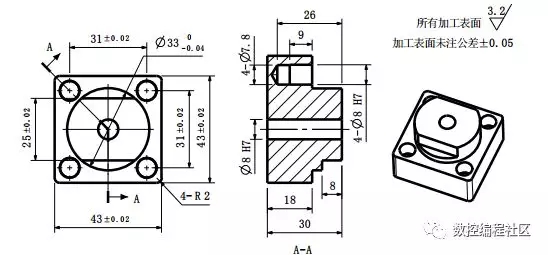

一日一例(5.24)

加工路线是:

钻中心孔→钻Φ7.8的孔→粗铣Φ33的圆台→粗铣25的台阶→精铣25的台阶→精铣Φ33的圆台→铰Φ8H7孔。

程序参考:

O0001

G91G28Z0 主轴直接回到换刀参考点

T3M6

G90G54G0X0Y0S1500M3 刀具初始化,选择用户坐标系为 G54

G43H3Z100.0M08

G99G81X15.5Y15.5Z-5.0R5.0F80 G81 钻孔循环指令钻中心孔

Y-15.5

X-15.5

Y15.5

G80M09

M05

G91G28Z0

T4M6

G90G54G0X0Y0S800M3

G43H4Z100.0M08

G99G73X15.5Y15.5Z-29.0Q2.0R5.0F60 G73 钻孔循环指令钻孔

Y-15.5

X-15.5

Y15.5

G80M09

M05

G91G28Z0

T1M6

G90G54G0X0Y0S600M3

G43H1Z100.0 1 号刀的长度补偿

X41.5Y0

Z5.0M08

G01Z-5.5F50

D1M98P100F120(D1=14) 用不同的刀具半径补偿值重复调用子程序去除工件的余量

D2M98P100F120(D2=6.2)

G01Z-11.0F50

D1M98P100F120(D1=14) 半径补偿值和切削速度传入子程序

D2M98P100F120(D2=6.2)

G01Z-8.0F50

D2M98P200F120(D2=6.2)

G0Z100.0M09

M05

G91G28Z0

T2M6

G90G54G0X0Y0S1100M3

G43H2Z100.0

X41.5Y0

Z5.0M08

G01Z-8.0F90

D3M98P200F130(D3=4) 用合适的刀具半径补偿,通过调用子程序完成精加工重复铣削一次,减小刀具弹性变形的影响

D3M98P200F130(D3=4)

G01Z-11.0F90

D4M98P100F130(D4=3.99)

D4M98P100F130(D4=3.99)

G0Z100.0M09

M05

G91G28Z0

T5M6

G90G54G0X0Y0S200M3

G43H5Z100.0

G98G81X15.5Y15.5R10.0Z-21.0F50 G81 循环指令铰孔

Y-15.5

X-15.5

Y15.5

G80M09

M05

M30

%

O100 O100 子程序(铣削 Φ33 的圆台)

X41.5Y0

G01G41Y25.0 刀具半径补偿有效,补偿值由主程序传入

G03X16.5Y0R25.0 圆弧切入

G02I-16.5J0 加工轨迹的描述,铣削整圆

G03X36.5Y-20.0R20.0 圆弧切出

G01G40Y0 刀具半径补偿取消

M99

%

%

O200 子程序(铣削 25±0.02 的台阶)

X41.5Y0

G01G41Y-12.5

X-20.0 直线切入

Y12.5 加工轨迹的描述

X41.5 直线切出

G01G40Y0

M99

%

%

G91G28Z0 铣工件上表面的程序,单独使用

T1M6

G90G54G0X0Y0S600M3

G43H1Z100.0

X45.0Y0

Z5.0 M08

G01Z0.F80

G01X35.0F130

G02I-35.0J0

G01X25.0

G02I-25.0J0

G01X15.0

G02I-15.0J0

G01X5.0

G02I-5.0J0

G0Z100.M09

M05

M30

%

该文章转自于:数控编程社区 https://mp.weixin.qq.com/s/I8UUZVWza1cPQADBLrRAfA

上一篇:8条氩弧焊的使用方法

下一篇:合金元素在钢中的作用